Abdul Rab Shaikh

Sales Engineer, Reon Energy Limited

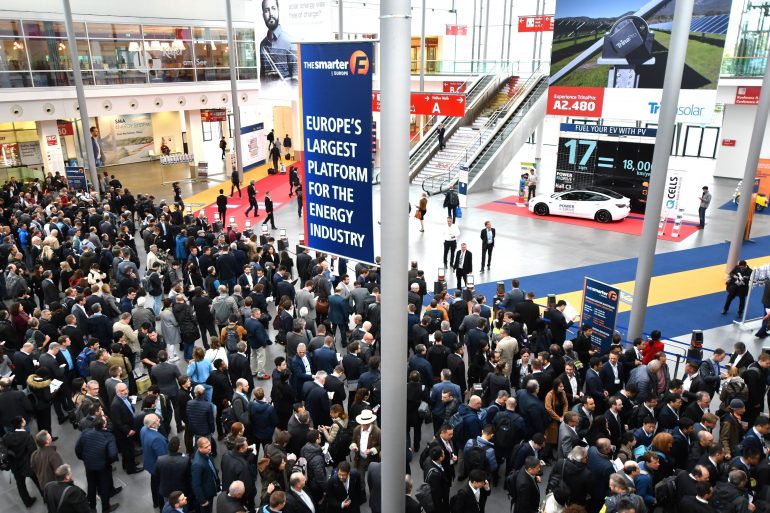

Intersolar Europe 2019 was held in Munich, Germany from 15th to 17th May. Intersolar is the largest PV Solar Exhibition in the world that attracts more than 50,000 attendees including manufacturers, project developers, renewable energy experts, and policymakers. This year the event covered various aspects of the Solar PV market and subsequent innovations in the Solar industry.

Day 1

Sleep deprived and starved, I rushed from Munich International Airport to Messe München just in time for the Intersolar exhibition. On stepping out of the airport, I was met with some cool breeze, enough to wash away my weariness.

I started off my first day exploring the Smart Solar PV Inverters and battery storage solutions. The most common PV inverters are still string and central inverters; however, these are not commercially feasible options for large scale solar solutions. The winner on Day 1 was smart battery storages mostly based on the lithium and zinc ion technologies. These smart storage options came with compact container sized solutions with a battery life of at least 5000 to 6000 cycles and flexibility to get charged from either grid or solar, based on availability.

Day 2

If I ever have a least favorite beverage, it must be sparkling water. Sticking with Soda to keep myself hydrated, I spent my second day at the exhibition exploring innovations in the field of PV modules. An interesting development that caught my attention was the Bifacial Solar Modules that can help produce power from both, the front and back, of the module. Such modules are especially ideal for desert regions where fine sand particles create maximum albedo effect and contribute towards an estimated 30% increase in energy generation with a negligible increase in manufacturing cost.

Day 3

If you consider yourself street smart, do try taking the train in Munich. I was lost between U-Bahn and S-Bahn terminologies, making navigation a huge challenge. After spending a good amount of my morning trying to decode the city map, I finally managed to reach the Intersolar exhibition. Here, I discovered smarter Operations and Maintenance (O&M) techniques that included heavy vehicles and remote-controlled robotic cleaners. Another interesting find was the manufacturing of structures based on concrete ballasts without the use of aluminum or galvanized steel. These structures are cost-effective, more reliable and sustainable, especially for harsher rooftops. Moreover, cables can now easily be laid out in open behind the panels that cut down on manhours for digging trenches.

Attending the Intersolar Europe 2019 offered a vivid perspective to the solar industry innovations and developments from across the globe. While not all innovations were cost-efficient in the Pakistani scenario, I intend to put better ideas especially for structures and cabling to test. And hopefully, prepare for another visit to attend the Intersolar Europe 2020..